Views: 0 Author: Site Editor Publish Time: 2025-10-31 Origin: Site

In today's fast-paced industrial world, high-performance materials are crucial. But how do we ensure long-lasting adhesion and durability in coatings and adhesives?

Aziridine crosslinkers have emerged as a game-changer. These highly reactive compounds are revolutionizing modern formulations by enhancing adhesion and extending product lifespan.

In this article, we’ll explore how aziridine crosslinkers are transforming industries by improving durability, wear resistance, and environmental stress resistance.

Aziridine crosslinkers are characterized by their highly reactive three-membered aziridine ring structure. This structure is particularly reactive with various polymer functional groups, such as hydroxyl, amine, and carboxyl groups. When the aziridine ring opens, it forms strong covalent bonds with these functional groups, creating a densely crosslinked polymer network. This high reactivity makes aziridine crosslinkers effective in improving adhesion and mechanical strength, especially in complex polymer systems.

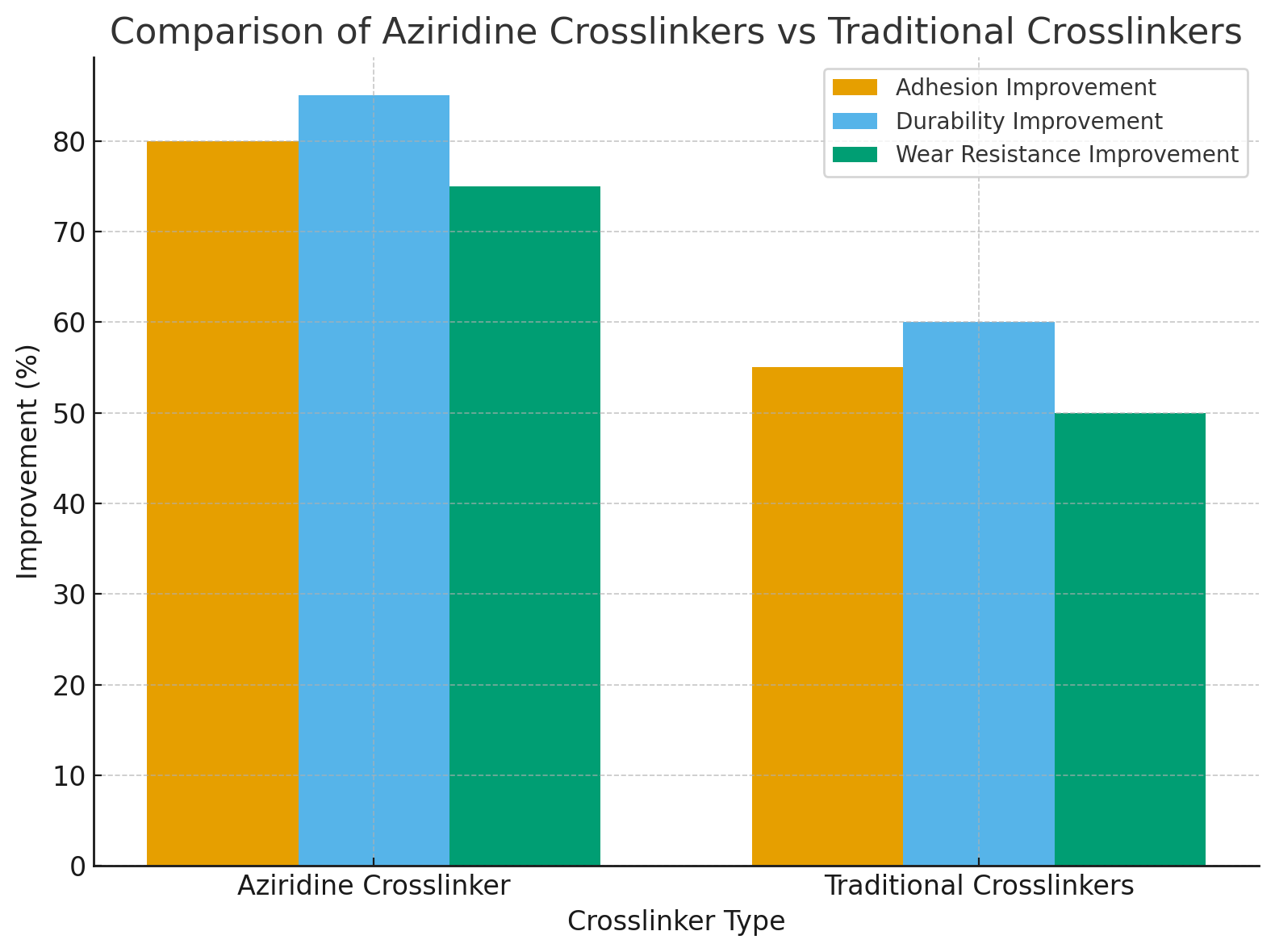

Traditional crosslinkers, such as melamine, isocyanates, and epoxy-based systems, have been used for decades to enhance polymer properties. However, aziridine crosslinkers offer distinct advantages. Unlike traditional options, aziridines react quickly at ambient temperatures, reducing the need for elevated curing temperatures or catalysts. This results in faster processing times and energy savings. Additionally, aziridine crosslinkers are more versatile, capable of bonding with a wider range of polymer systems, including both waterborne and solvent-based formulations.

One of the most significant advantages of aziridine crosslinkers is their ability to bond effectively with challenging substrates, including metals, plastics, and composites. These materials often present challenges in adhesion, but aziridine crosslinkers form robust chemical bonds with the substrate, ensuring that the coating or adhesive remains intact over time. This enhanced adhesion is especially crucial in industries such as automotive, aerospace, and construction, where reliable bonding is essential for product performance and safety.

Aziridine crosslinkers offer the added benefit of faster curing at ambient or moderate temperatures. This reduces energy consumption and shortens processing times, making them a more efficient option for manufacturers. For example, coatings and adhesives that use aziridine crosslinkers can cure at room temperature, eliminating the need for high-temperature ovens or curing equipment, thus cutting energy costs and improving production efficiency.

Aziridine crosslinkers significantly enhance the durability of coatings and adhesives. They provide excellent resistance to UV radiation, water exposure, and chemical wear. This makes them ideal for applications where long-term protection is necessary, such as exterior coatings, automotive finishes, and industrial adhesives. Their ability to withstand environmental stress ensures that the products maintain their integrity and performance over extended periods, reducing maintenance needs and increasing overall product lifespan.

The mechanical strength of materials treated with aziridine crosslinkers is significantly improved. These crosslinkers create a more robust polymer network, reducing degradation under physical stress, such as abrasion or impact. For industries like electronics, automotive, and industrial machinery, this enhanced wear resistance is crucial for maintaining the performance and reliability of coatings and adhesives. Aziridine-based formulations are particularly effective in demanding environments, where mechanical stress and wear are constant concerns.

Aziridine crosslinkers help extend the lifespan of products by improving their performance in extreme conditions. Whether exposed to high temperatures, humidity, or chemical exposure, coatings and adhesives formulated with aziridine crosslinkers are more durable. This makes them ideal for use in harsh industrial environments, such as in construction machinery, offshore equipment, and aerospace components. By enhancing the longevity of these materials, aziridine crosslinkers contribute to reduced downtime and maintenance costs.

Aziridine crosslinkers are highly versatile and compatible with various polymer systems, including both waterborne and solvent-based formulations. They can be easily integrated into resins, solvents, and additives, making them a flexible solution for a wide range of applications. Whether used in acrylics, polyurethanes, or epoxies, aziridine crosslinkers maintain their effectiveness, providing consistent performance across different polymer types. This flexibility allows manufacturers to create formulations tailored to specific needs without compromising on quality or performance.

In addition to improving the mechanical properties of coatings and adhesives, aziridine crosslinkers also contribute to formulation stability. They mix uniformly with resins, solvents, and additives, ensuring consistent viscosity and smooth application. This stability is crucial for preventing issues like phase separation or incomplete crosslinking, which can affect the final product's performance. Aziridine crosslinkers ensure that formulations maintain their desired properties over time, even under challenging storage or environmental conditions.

As industries increasingly prioritize sustainability, aziridine crosslinkers provide an eco-friendly alternative to traditional crosslinking agents. By enabling stronger bonds at lower dosages, aziridine crosslinkers help reduce solvent content and volatile organic compounds (VOCs), making formulations greener and more environmentally friendly. This reduction in VOC emissions is particularly beneficial in industries where environmental regulations are strict, such as automotive and construction.

While aziridine crosslinkers offer numerous benefits, it is important to handle them with care due to their reactivity. Proper safety measures, such as using personal protective equipment (PPE) and adhering to storage guidelines, are crucial to minimizing risks. Compared to some traditional crosslinkers, aziridines may present lower long-term hazards when used correctly, but proper handling remains essential for ensuring safety in both manufacturing and end-use applications.

Aziridine crosslinkers are widely used in automotive coatings to improve adhesion and durability. They create a strong bond between the coating and the vehicle surface, ensuring that the paint remains intact even under harsh environmental conditions. This enhances the lifespan of the vehicle's finish, reducing the frequency of touch-ups and maintenance.

In the aerospace industry, where performance and reliability are critical, aziridine crosslinkers are used in coatings and adhesives to withstand extreme temperatures and pressure. These crosslinkers provide long-lasting protection for aircraft components, ensuring that the coatings and adhesives remain effective throughout the service life of the aircraft.

Aziridine-based coatings are also used in industrial equipment to enhance resistance to wear and tear. These coatings protect machinery and tools from corrosion, abrasion, and chemical exposure, ensuring that the equipment remains functional for longer periods. This is especially important in industries like mining, manufacturing, and offshore oil and gas, where equipment is subjected to harsh working conditions.

Aziridine crosslinkers are transforming modern formulations with superior adhesion and enhanced durability. They offer resistance to environmental stress and bond effectively with diverse substrates. These crosslinkers are becoming essential in industries like automotive, aerospace, and manufacturing. As demand grows for high-performance, eco-friendly solutions, aziridine crosslinkers will play a key role in advancing coatings and adhesives. Companies like MSN Chemical provide these innovative products, helping manufacturers meet and exceed performance standards.

A: An aziridine crosslinker is a highly reactive compound that forms strong covalent bonds with polymer chains, improving adhesion, durability, and mechanical strength in coatings and adhesives.

A: Aziridine crosslinkers bond effectively with a wide variety of substrates, including metals and plastics, enhancing adhesion in challenging environments, especially in automotive and aerospace applications.

A: Aziridine crosslinkers react faster at lower temperatures, offering superior performance with reduced energy consumption and faster curing times compared to traditional crosslinkers like melamine or isocyanates.

A: Aziridine crosslinkers enhance durability, wear resistance, and environmental stress resistance, making them ideal for high-performance applications in industries like manufacturing, automotive, and construction.

A: Yes, aziridine crosslinkers help reduce VOC emissions, contributing to greener and more sustainable formulations, meeting modern environmental standards.